Agents - Bliss

Sevale Engineering are agents for Bliss Industries who manufactures hammermills, pellet mills, pellet coolers, crumblers, and other products for the grain, feed and milling industries.

Bliss Industries, LLC., was formed in 1981 in Newkirk, OK. Over the years, they have developed into a leading manufacturer of processing equipment for the renewable fuels, industrial, agricultural, food, chemical, wood, fibre, and other industries. Bliss specializes in equipment for size reduction of materials, the creation of pellets from various materials, and the cooling of pellets and other industrial products. Today, Bliss Industries is privately owned, and offers a professional management team, a highly knowedgeable and experienced staff and labour force, and the most efficient and high quality equipment available.

Pioneer Pellet Mills

Developed from a design concept proven worldwide since its introduction in 1975, the range of Pioneer Pellet Mills continues to expand. Designed with max efficiency overall durability, ease of operation, and maintenance. As core principles, Bliss Pellet Mills provide lower operating costs to each owner. With a wide range of die sizes, die speeds, and drive power, Bliss can design a system to meet your requirements with both quality and cost-effectiveness.

Nothing is more important to your business than long term performance. All interior components of a Bliss Pellet Mill are selected and manufactured for superior performance and wear. The result is maximum uptime that increases revenue and diminishes the chances of premature component failure.

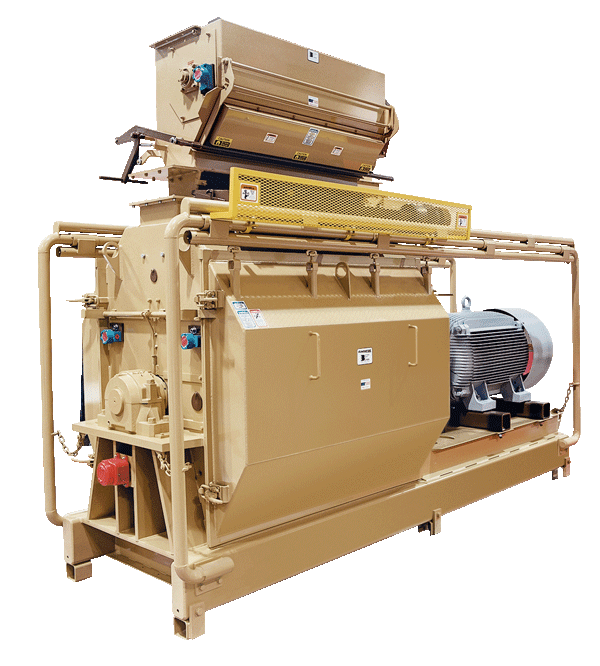

Eliminator Hammermills

Increase your productivity and profits with a Bliss Eliminator Hammermill. Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, one-piece plate housing, 3/8″ plate doors, octagonal shaped housing, double drilled rotors, and one-piece screen carriage maximize your grinding efficiency. Every Hammermill is individually sized based on research and decades of experience to fit your unique application and needs.

Each Eliminator is backed with our “post-sales service program” providing continual support via our fully equipped and experienced service team and a complete line of OEM parts. The Eliminator Hammermills are used in an extensive variety of applications including: wood, paper, cereal grains, by-products, oil seeds, food products, pet, and aquatic feeds.